Description:

1 component profiles

ModelBF350-3AA/1.5AA

Sensitivity factor: 2

Strain limit: 2%

Grid wire: longxwide2x3.5mm

Base size: longxThe width of 5X4.5mm

Base material: modified phenolic substrate.

Grid wire material

Resistance: 350 ohms

Fatigue life: >10000000 times

Flux: ordinary rosin solder

The working principle of resistance strain gauge is based on the strain effect produced by mechanical deformation, namely the role of conductor or semiconductor materials in the external force when the resistance value changes, this phenomenon is called "strain effect".

The strain gauge is attached to the object to be measured, so that it is bent along with the strain of the measured object. A lot of metal in the mechanical bending of its resistance will change.

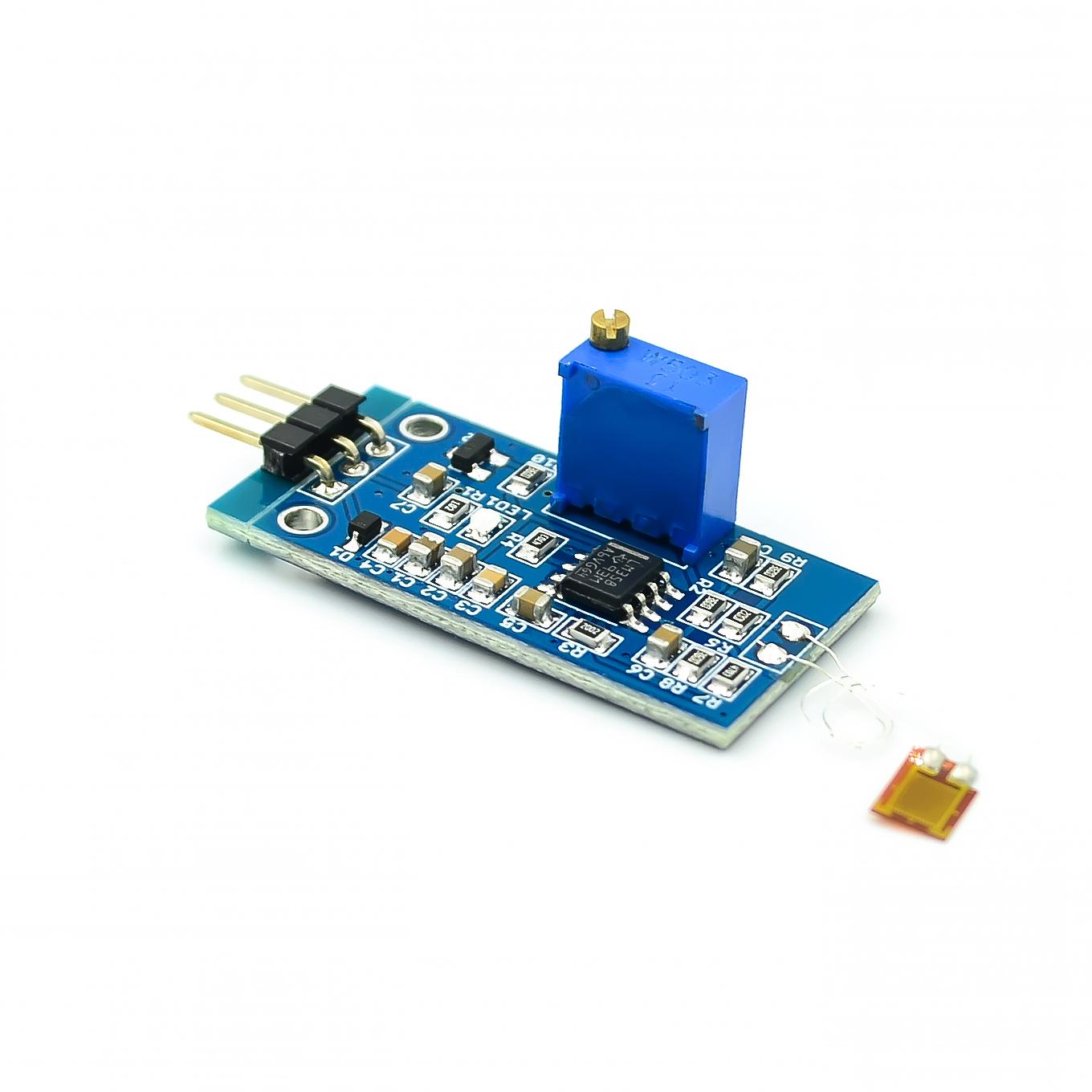

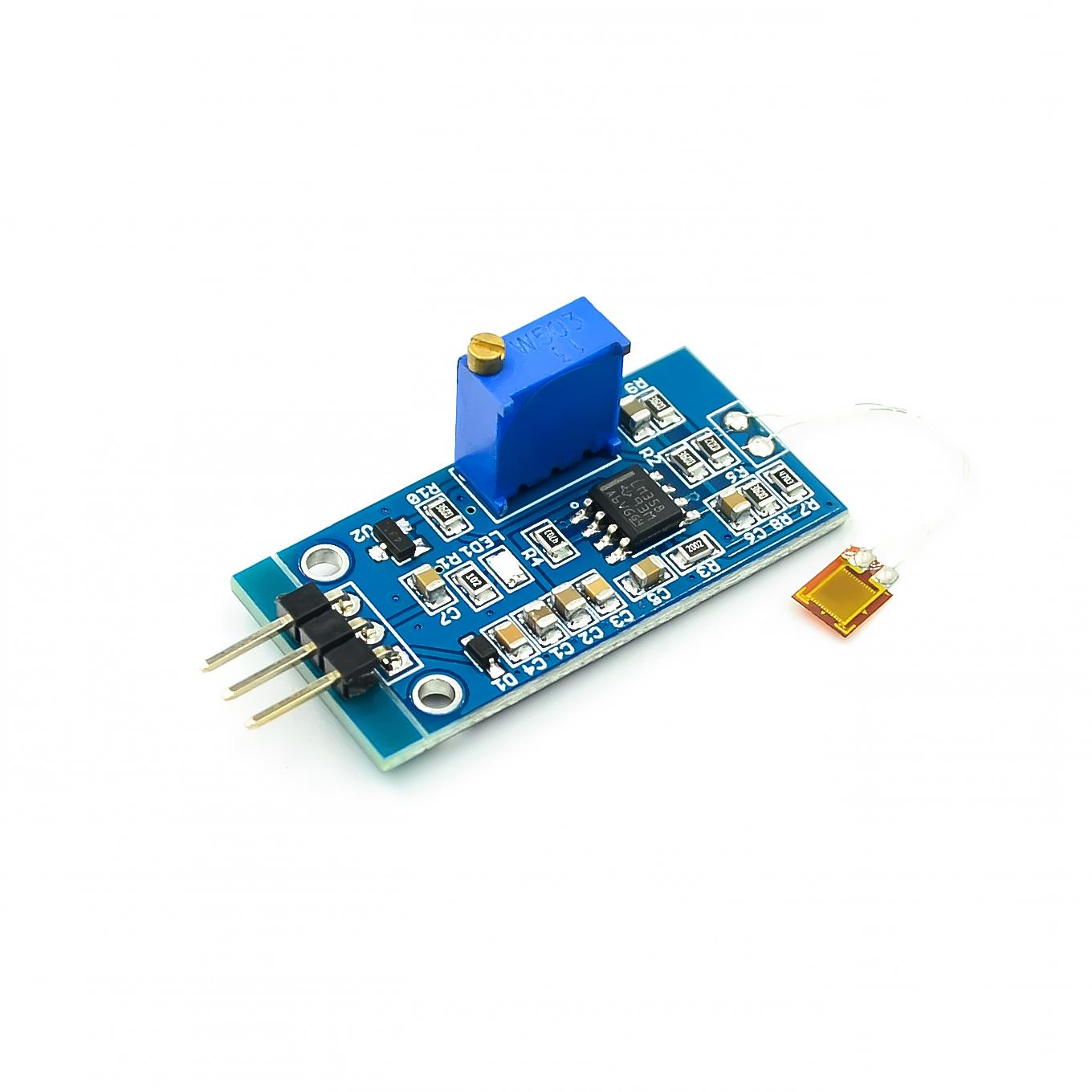

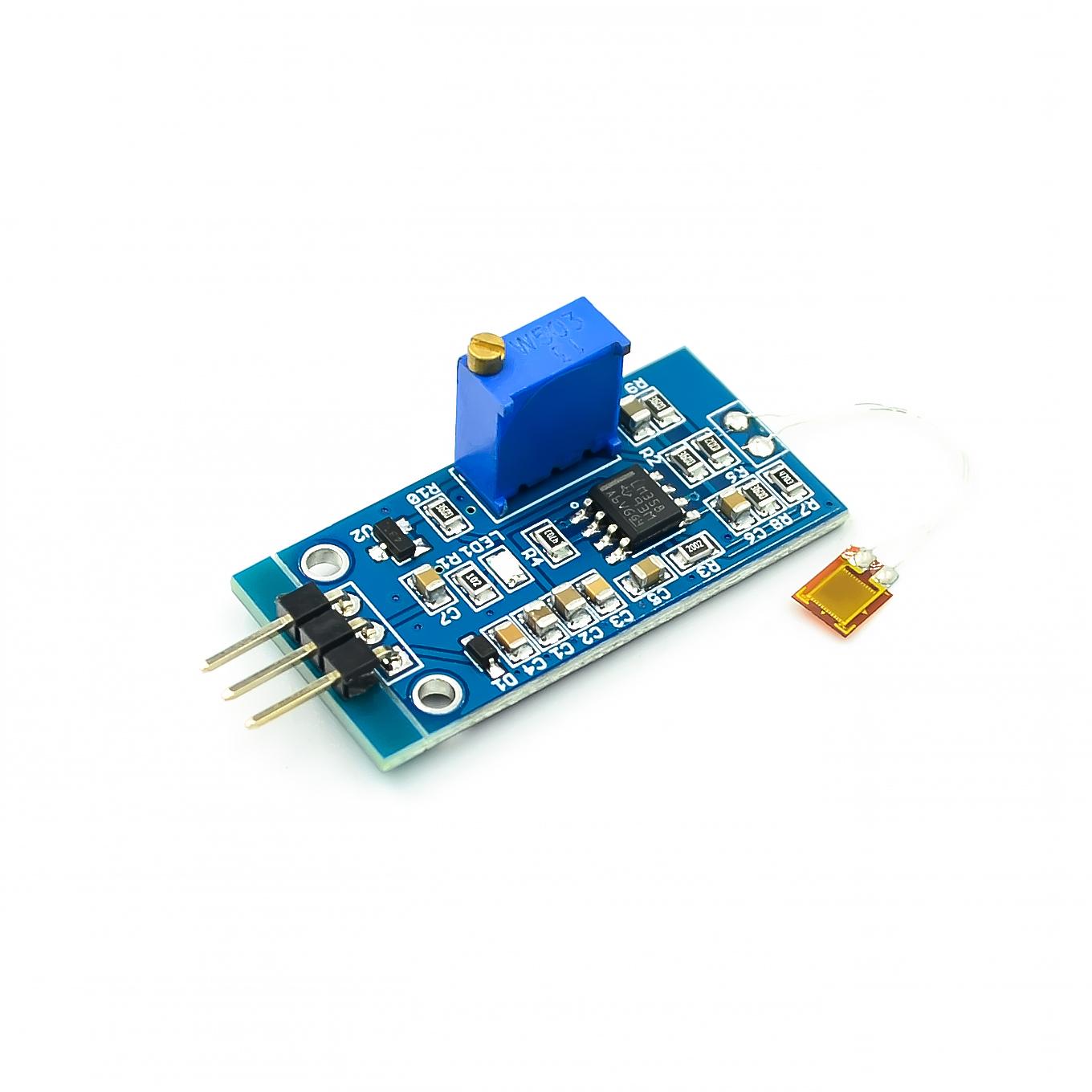

2 product profiles

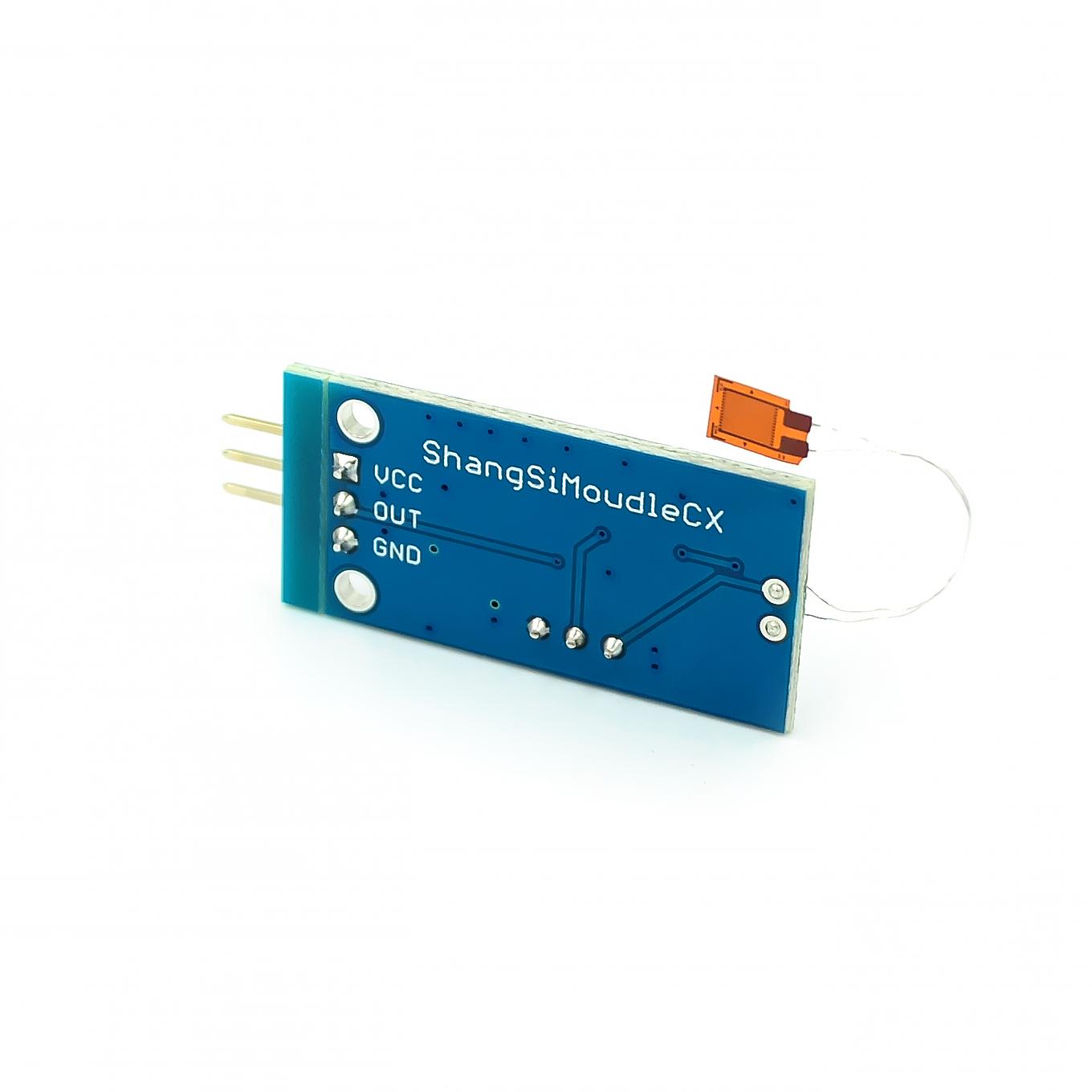

Voltage: 5V

Two tube reverse protection ~ (to prevent the power supply connected to the back)

On board with a blue LED power indicator

Analog output

The higher the bending degree, the higher the output voltage

Zero potentiometer

Can be used to adjust the output voltage of the starting voltage

Output analog voltage 0-3.5V

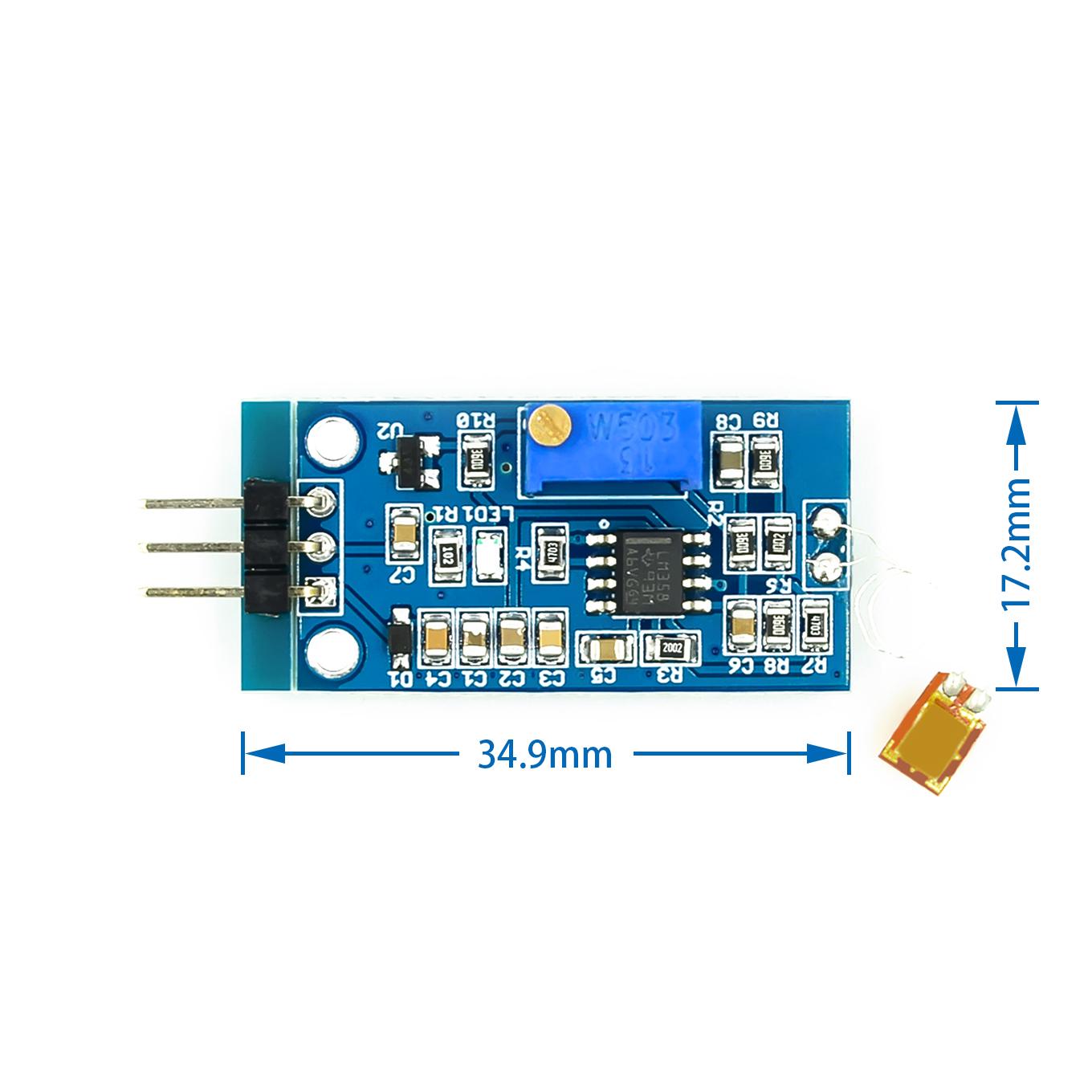

Board size: 32 X 17 mm

The board is printed with pin output definition

(bending strain gauge can change the output voltage)

Q: how do you use this principle?

This is the bending sensor

Said the principle is also to detect the degree of bending, the strain piece affixed to the carrier, such as: Iron and aluminum plastic film and then bending the carrier, the strain gauge to detect the bending output voltage will change.

The strain gauge can be affixed to any object, the bending is detected, and then the voltage of the module is bent.

(welding strain films should pay attention to the temperature is not too high 300 degrees below the appropriate welding time of 3 seconds, please use the welding wire cord is appropriate)